C85 Serje liga ta ' l-aluminju li jaġixxu pnewmatiċi ċilindru ta ' l-arja standard Ewropew

Deskrizzjoni tal-Prodott

Id-disinn taċ-ċilindru ġie ottimizzat bir-reqqa, bl-użu ta 'sistema ta' siġillar affidabbli u materjali reżistenti għall-ilbies biex jiżguraw tħaddim affidabbli fit-tul. Għandu wkoll apparat buffer aġġustabbli li jista 'jnaqqas il-forza tal-impatt u jestendi l-ħajja tas-servizz taċ-ċilindru.

Iċ-ċilindri tas-serje C85 għandhom metodi multipli ta 'installazzjoni u konnessjoni u jistgħu jintużaw flimkien ma' diversi tagħmir pnewmatiku u sistemi ta 'kontroll. Jista 'wkoll jiġi personalizzat skont ir-rekwiżiti speċifiċi tal-klijenti biex jissodisfa l-ħtiġijiet ta' xenarji ta 'applikazzjoni differenti.

Speċifikazzjoni Teknika

| Daqs tat-toqba (mm) | 8 | 10 | 12 | 16 | 20 | 25 |

| Modalità ta' Reazzjoni | Azzjoni doppja | |||||

| Midja ta' Ħidma | Arja mnaddfa | |||||

| Pressjoni tax-Xogħol | 0.1~0.9Mpa(1~9kgf/cm²) | |||||

| Pressjoni tal-Prova | 1.35Mpa (13.5kgf/cm²) | |||||

| Temperatura tax-Xogħol | -5 ~ 70 ℃ | |||||

| Modalità Buffering | Kuxxin tal-Gomma / Buffering tal-Ajru | |||||

| Daqs tal-Port | M5 | 1/8 | ||||

| Materjal tal-Korp | Stainless Steel | |||||

Stroke taċ-ċilindru

| Daqs tal-bore (mm) | Stroke Standard (mm) | Max.stroke (mm) | stroke permissibbli (mm) |

| 8 | 10 25 40 50 80 100 | 300 | 500 |

| 10 | 10 25 40 50 80 100 | 300 | 500 |

| 12 | 10 25 40 50 80 100 125 150 175 200 | 300 | 500 |

| 16 | 10 25 40 50 80 100 125 150 175 200 | 300 | 500 |

| 20 | 10 25 40 50 80 100 125 150 175 200 250 300 | 500 | 1000 |

| 25 | 10 25 40 50 80 100 125 150 175 200 250 300 | 500 | 1000 |

Għażla ta 'Swiċċ tas-Sensor

| Modalità/Bore Size | 8 | 10 | 12 | 16 | 20 | 25 |

| Swiċċ tas-Sensor | CS1-F CS1-U D-Z73 CS1-S | |||||

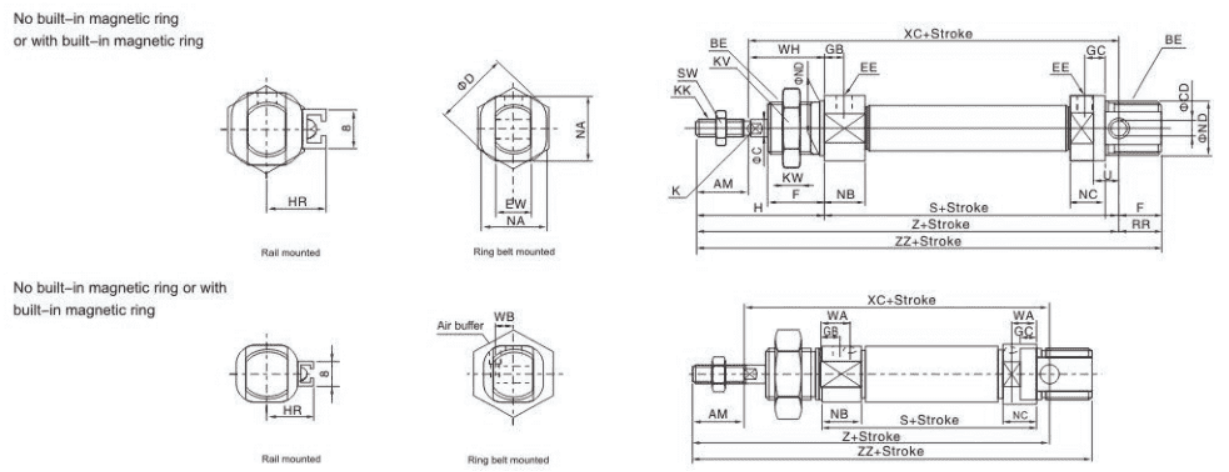

| Daqs tat-toqba (mm) | AM | BE | φC | φDC | φD | EW | F | EE | GB | GC | WA | WB | H | HR | K | KK |

| 8 | 12 | M12X1.25 | 4 | 4 | 17 | 8 | 12 | M5X0.8 | 7 | 5 |

|

| 28 | 10 |

| M4X0.7 |

| 10 | 12 | M12X1.25 | 4 | 4 | 17 | 8 | 12 | M5X0.8 | 7 | 5 |

|

| 28 | 10.5 |

| M4X0.7 |

| 12 | 16 | M16X1.5 | 6 | 6 | 20 | 12 | 17 | M5X0.8 | 8 | 6 |

|

| 38 | 14 | 5 | M6X1 |

| 16 | 16 | M16X1.5 | 6 | 6 | 20 | 12 | 17 | M5X0.8 | 8(5.5) | 6(5.5) | 9.5 | 6.5 | 38 | 14 | 5 | M6X1 |

| 20 | 20 | M22X1.5 | 8 | 8 | 28 | 16 | 20 | G1/8 | 8 | 8 | 11 | 9 | 44 | 17 | 6 | M8X1.25 |

| 25 | 22 | M22X1.5 | 10 | 8 | 33.5 | 16 | 22 | G1/8 | 8 | 8 | 11 | 10 | 50 | 20 | 8 | M10X1.25 |

| Daqs tat-toqba (mm) | KV | KW | NB | NC | NA | φND | RR | S | SW | U | WH | XC | Z | ZZ |

| 8 | 17 | 7 | 11.5 | 9.5 | 15 | 12 | 10 | 46 | 7 | 6 | 16 | 64 | 76 | 86 |

| 10 | 17 | 7 | 11.5 | 9.5 | 15 | 12 | 10 | 46 | 7 | 6 | 16 | 64 | 76 | 86 |

| 12 | 22 | 6 | 12.5 | 10.5 | 18 | 16 | 14 | 50 | 10 | 9 | 22 | 75 | 91 | 105 |

| 16 | 22 | 6 | 12.5(12.5) | 10.5(12.5) | 18 | 16 | 13 | 56 | 10 | 9 | 22 | 82 | 98 | 111 |

| 20 | 30 | 7 | 15 | 15 | 24 | 22 | 11 | 62 | 14 | 12 | 24 | 95 | 115 | 126 |

| 25 | 30 | 7 | 15 | 15 | 30 | 22 | 11 | 65 | 17 | 12 | 28 | 104 | 126 | 137 |